Uninsulated wire plays a crucial role in industrial and electrical applications. It is essential for many tasks. It works well in grounding and high-temperature applications. It is also useful in complex manufacturing processes. Its benefits make it a must-have. For high-quality uninsulated wire, choose Pelican Wire. They are a trusted leader in custom wire and cable solutions. This guide covers uninsulated wire. We’ll look at its uses, benefits, and why Pelican Wire is your best choice for premium wire products.

What Is Uninsulated Wire?

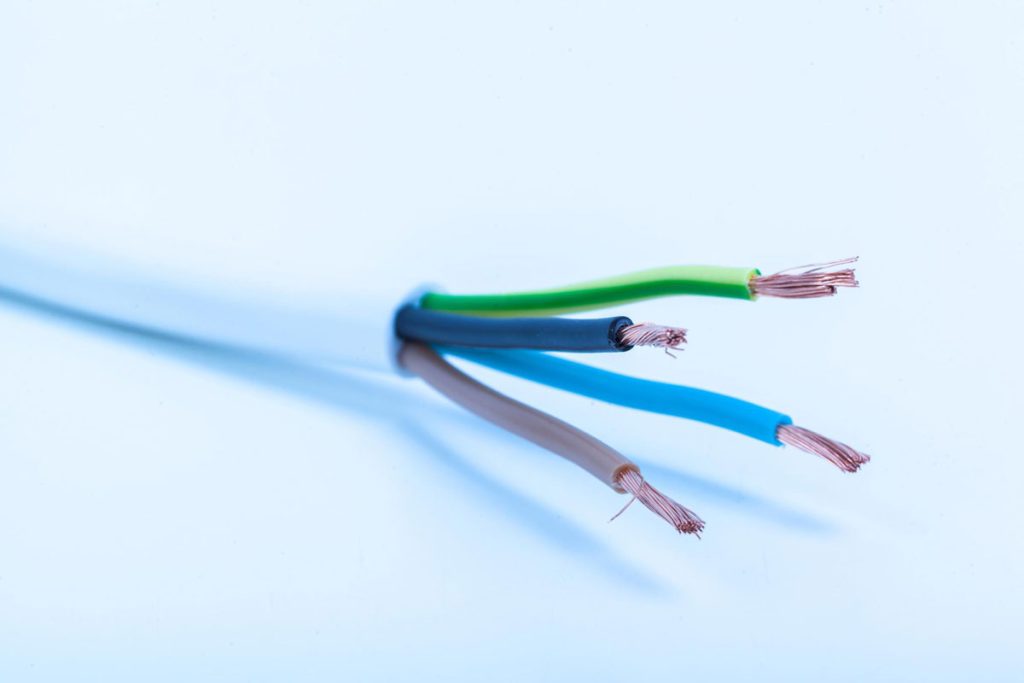

Uninsulated wire, or bare wire, is electrical wire without a protective coating. It differs from standard insulated wire, which is wrapped in materials like PVC, rubber, or Teflon. In contrast, uninsulated wire is made only of conductive metals like copper, aluminum, or stainless steel.

Uninsulated wire lacks an insulating layer, so it conducts electricity directly. This makes it great for grounding, high-temperature uses, and electrical bonding. Not having insulation makes it easy to adapt and be flexible in many industrial uses.

Uninsulated wire is often chosen when insulation is too bulky or hinders heat dissipation. Choosing between insulated and uninsulated wires in electrical engineering depends on several factors. You must consider the environment, safety needs, and how well the wire conducts electricity.

Common Uses of Uninsulated Wire

1. Grounding & Electrical Bonding

One of the primary applications of uninsulated wire is in grounding systems. Grounding is key in electrical networks. It protects against surges and lowers the risk of electrocution. Bare copper wire is commonly used for this purpose due to its excellent conductivity and resistance to corrosion.

Uninsulated grounding wire is standard in homes, businesses, and factories. It connects electrical systems to the earth. This helps prevent voltage fluctuations and keeps everyone safe.

2. High-Temperature Applications

Aerospace, automotive, and power generation industries need wiring to withstand extreme temperatures. Uninsulated wire, made from nickel or stainless steel alloys, is often used in heating elements, thermocouples, and furnace wiring. Standard insulated wire would break down in these applications.

When exposed to extreme heat, insulation materials can melt, burn, or degrade, potentially leading to electrical failures. This is why uninsulated wire is the go-to solution for applications with critical heat resistance.

3. Welding & Metal Fabrication

Uninsulated wire is extensively used in welding applications. Welding electrodes, for instance, rely on bare wire to create a strong electrical connection. No insulation means better conductivity, which is key for high-quality welds.

The welding industry depends on the superior performance of uninsulated wire, ensuring a stable arc and consistent welding results. Various metals are used depending on the specific requirements of the welding process.

4. Industrial & Manufacturing Processes

In industries that require custom wiring solutions, such as robotics and automation, uninsulated wire is used to wind coils, connect components, and assemble electrical circuits. Its flexibility and high conductivity make it a preferred choice for manufacturers.

Uninsulated wire is an integral part of modern machinery and industrial processes, from motor windings to solenoids and electromagnetic applications.

5. Jewelry & Artistic Applications

Uninsulated wire isn’t just for industry. It’s also popular in jewelry making, sculptures, and other art forms. Artists and craftsmen prefer uninsulated wire because it is easy to shape, mold, and solder into intricate designs.

Uninsulated silverwire, gold, and copper uninsulated wire are particularly popular in jewelry crafting, where conductivity and malleability are important factors.

Benefits of Using Uninsulated Wire

1. Superior Conductivity

Without insulation, uninsulated wire allows for direct electrical conductivity, making it ideal for applications requiring minimal resistance.

Electrical conductivity is key for many high-performance uses. The purity of the metal in uninsulated wire greatly impacts its efficiency.

2. Greater Flexibility

Since there is no additional insulating material, uninsulated wire remains more flexible than its insulated counterparts. This flexibility makes handling, cutting, and shaping for specific applications easier.

Manufacturers often prefer uninsulated wire for applications requiring tight bends, intricate wiring, or easy customization.

3. Cost-Effectiveness

Uninsulated wire is generally more affordable than insulated wire since it does not require additional insulation materials. It’s a cost-effective choice for bulk use in manufacturing and industry.

4. Higher Temperature Resistance

For applications that involve extreme heat, uninsulated wire performs better than insulated wire. It has no outer coating that could melt or degrade in high-temperature environments.

5. Easy Customization

Uninsulated wire can be easily customized to meet specific requirements. It can be cut to precise lengths, twisted, or combined with other conductive materials to create specialized wire configurations.

Why Choose Pelican Wire for Uninsulated Wire?

With over 50 years of experience in wire and cable manufacturing, Pelican Wire has built a reputation for providing top-quality uninsulated wire for a wide range of industries. Here’s why Pelican Wire is the preferred choice:

1. High-Quality Materials

Pelican Wire sources only the finest raw materials, ensuring that their uninsulated wire meets the highest industry standards. Whether you need copper, nickel, or stainless steel wire, you can trust Pelican Wire for durability and performance.

2. Custom Wire Solutions

Every project is unique, and Pelican Wire understands that. They offer customized wire solutions tailored to your application, including precise gauges, lengths, and alloys.

3. Industry Expertise

Pelican Wire serves aerospace, medical, defense, and industrial manufacturing industries. Their expertise ensures you receive the best wire solutions for even the most demanding applications.

4. Strict Quality Control

With ISO-certified manufacturing processes, Pelican Wire guarantees superior quality and performance. Each batch of uninsulated wire undergoes rigorous testing to ensure reliability and safety.

5. Fast & Reliable Delivery

Pelican Wire understands the importance of timely deliveries. Their efficient production and supply chain management ensures that you receive your order on time, every time.

Conclusion

Uninsulated wire plays a key role in many industries. It is used for electrical grounding, high-temperature tasks, and artistic projects. Its superior conductivity, flexibility, and cost-effectiveness make it a valuable choice for numerous applications.

For the highest-quality uninsulated wire, trust Pelican Wire. They are committed to excellence. Their customized solutions and industry expertise help you get the best product. Explore Pelican Wire’s uninsulated wire offerings today and experience the difference in quality and performance!