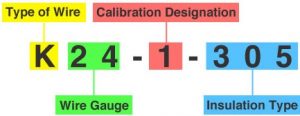

Thermocouple Wire Part Numbering System

Example Thermocouple Wire Part Number: K24-1-305

Thermocouple Wire Part Numbering System |

|

|---|---|

Type of Wire |

|

| J | |

| K | |

| T | |

| E | |

Wire Gauge |

|

| 16-40 AWG¹ | |

Calibration Designation |

|

| 0 | Thermocouple Grade, Solid, Single Leg |

| 1 | Thermocouple Grade, Solid, Standard Limits |

| 2 | Thermocouple Grade, Solid, Special Limits |

| 3 | Thermocouple Grade, Stranded, Standard Limits |

| 4 | Thermocouple Grade, Stranded, Special Limits |

| 5 | Extension Grade, Solid, Standard Limits |

| 6 | Extension Grade, Solid, Special Limits |

| 7 | Extension. Grade, Stranded, Standard Limits |

| 8 | Extension Grade, Stranded, Special Limits |

| 9 | Thermocouple Grade, Stranded, Single Leg |

Insulation Type |

|

| (See below table) | |

¹Special sizes available upon request

| Temperature Ratings | Physical Properties | |||||||

|---|---|---|---|---|---|---|---|---|

| Part # | Type of Insulation | Max Continuous Temp. | Max Instantaneous Temp. | Abrasion Resistance | Moisture Resistance | Chemical Resistance | ||

| 301 | Vitreous Silica Braid / Vitreous Silica Braid | 871°C | 1600°F | 1093°C | 2000°F | * * | * | * |

| 302 | Double Glass Braid Singles / Glass Braid Duplex | 482°C | 900°F | 538°C | 1000°F | * * * | * * * | * * * |

| 303 | Enamel, Glass Braid Singles / Glass Braid Duplex | 482°C | 900°F | 538°C | 1000°F | * * | * * * | * * * |

| 304 | Standard Glass Braid Singles / Glass Braid Duplex | 482°C | 900°F | 538°C | 1000°F | * * | * * * | * * * |

| 305 | Double Glass Wrap Singles / Glass Braid Duplex | 482°C | 900°F | 427°C | 800°F | * * | * * * | * * * |

| 306 | Non Impregnated Glass Braid / Non Impregnated Glass Braid Duplex | 482°C | 900°F | 427°C | 800°F | * | * | * * |

| 308 | Double Cotton Braid Singles / Cotton Braid Duplex | 88°C | 190°F | 120°C | 248°F | * * * | * * * | * |

| 310 | Skive TFE Tape, TFE Impreg Glass Braid Singles / Fused TFE Tape Duplex | 260°C | 500°F | 538°C | 1000°F | * * * | * * * * | * * * * |

| 311 | “S” Glass No Binder | 704°C | 1300°F | 871°C | 1600°F | * * | * * | * * * |

| 321 | “S” Glass w/ Binder | 704°C | 1300°F | 871°C | 1600°F | * * | * * | * * * |

| 350 | Ceramic Fiber Braid/Ceramic Fiber Braid Duplex | 1204°C | 2200°F | 1427°C | 2600°F | * * | * * | * * |

| 355 | Ceramic Fiber Braid/Ceramic Fiber Braid Duplex Medium Build | 1204°C | 2200°F | 1427°C | 2600°F | * * | * * | * * |

| 365 | Vitreous Silica Braid / Vitreous Silica Braid Medium Build | 871°C | 1600°F | 1093°C | 2000°F | * * | * | * |

| 501 | Polyvinyl Singles / Nylon Duplex | 105°C | 221°F | 120°C | 248°F | * * * * | * * * * | * * * |

| 502 | Polyvinyl Singles / Polyvinyl Duplex | 105°C | 221°F | 105°C | 221°F | * * * | * * * * | * * * |

| 504 | Nylon Singles / Nylon Duplex | 150°C | 302°F | 130°C | 266°F | * * * * | * * * | * * * |

| 505 | PVC Single / Fused for Ripcord Duplex, No Jacket | 105°C | 221°F | 105°C | 221°F | * * * | * * * * | * * * |

| 506 | 5 Mils FEP Singles / 5 Mils FEP Duplex (may vary 5-7) | 204°C | 400°F | 260°C | 500°F | * * * * | * * * * | * * * * |

| 507 | 10 Mils FEP Singles / 10 Mils FEP Duplex (may vary 8-10) | 204°C | 400°F | 260°C | 500°F | * * * * | * * * * | * * * * |

| 508 | Fused TFE Tape Singles / Fused TFE Tape Duplex | 260°C | 500°F | 316°C | 600°F | * * * | * * * * | * * * * |

| 509 | FEP Singles / Twisted pair with drain wire / Alum. mylar or Polyimide / FEP Duplex | 204°C | 400°F | 260°C | 500°F | * * * * | * * * * | * * * * |

| 510 | PVC Singles / Twisted pair with drain wire / Alum. mylar / PVC Duplex | 105°C | 221°F | 105°C | 221°F | * * * | * * * * | * * * |

| 511 | Polyimide Singles / Polyimide Twisted Pair (no jacket) | 260°C² | 600°F | 427°C | 800°F | * * * * | * * * * | * * * * |

| 512 | Polyimide Singles with Tracers / Polyimide Duplex | 260°C² | 600°F | 427°C | 800°F | * * * * | * * * * | * * * * |

| 513 | Polyimide Singles / Polyimide Duplex | 260°C² | 600°F | 427°C | 800°F | * * * * | * * * * | * * * * |

| 514 | ETFE Singles / ETFE Duplex | 150°C | 302°F | 200°C | 392°F | * * * * | * * * * | * * * * |

| 515 | ETFE Singles / Twisted Pair / ETFE Duplex | 150°C | 302°F | 200°C | 392°F | * * * * | * * * * | * * * * |

| 516 | PFA Singles / PFA Duplex | 260°C | 500°F | 290°C | 550°F | * * * * | * * * * | * * * * |

² Polyimide tape will withstand 316°C but the laminate FEP layer will dissolve at temperatures above 260°C

| KEY | |

|---|---|

| * | Poor |

| * * | Fair |

| * * * | Good |

| * * * * | Excellent |