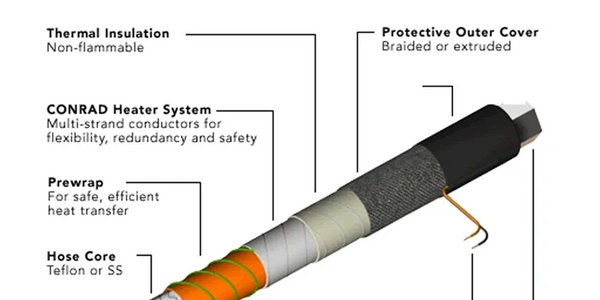

This technical description details a custom-engineered resistance wire designed for use in heated fluid delivery systems, specifically within mobile, insulated foam-in-place applications. This wire solution is tailored to meet stringent resistance and insulation requirements for consistent and reliable performance.

Conductor Design and Properties:

The conductor comprises seven strands of a high-stability resistance alloy, each with a diameter of 0.021 inches. This stranded construction offers enhanced flexibility and fatigue resistance compared to a solid conductor of equivalent cross-sectional area, crucial for applications involving repeated bending and flexing. The alloy is selected for its precise and consistent resistance characteristics, exhibiting a nominal resistance of 0.956 Ohms per foot. This specific resistance value ensures accurate and predictable heat generation within the heated hose. The stranded configuration also allows for a more even heat distribution across the wire’s cross-section.

Insulation Material and Properties:

The conductor is insulated with a 0.013-inch thick layer of yellow Fluorinated Ethylene Propylene (FEP). FEP is a high-performance fluoropolymer known for its excellent electrical insulation properties, chemical inertness, and wide operating temperature range. This insulation material provides a reliable barrier against electrical shorts and environmental factors, ensuring the longevity and safety of the heated hose. The yellow color of the insulation facilitates easy identification and traceability during assembly and maintenance. The insulation provides a high degree of protection from the chemicals commonly found in foam-in-place delivery systems.

Finished Dimensions and Construction:

The nominal finished diameter of the insulated wire is 0.047 inches. This precise diameter is critical for ensuring proper fit and integration within the heated hose assembly. The construction of the wire, combining the stranded conductor and FEP insulation, is optimized for flexibility, durability, and consistent performance in demanding applications.

Application and Performance:

This custom-engineered resistance wire is designed for integration into heated hoses that form part of a mobile, insulated foam-in-place delivery system. The specified resistance and insulation properties enable precise temperature control and reliable operation of the heating system. The stranded conductor design ensures flexibility and durability, while the FEP insulation provides robust protection against electrical shorts and chemical exposure. The wire is designed for high volume manufacturing and consistent quality. This design enables precise control of the foam’s temperature during application, ensuring consistent foam properties.

Technical Considerations:

- Resistance Tolerance: The nominal resistance value is typically accompanied by a tolerance specification, which defines the acceptable range of variation.

- Temperature Coefficient of Resistance (TCR): The TCR of the alloy is a critical parameter, as it determines how the resistance changes with temperature.

- Voltage Rating: The insulation material and thickness determine the voltage rating of the wire.

- Environmental Resistance: The FEP insulation provides excellent resistance to moisture, chemicals, and UV radiation.

- Flex Life: The stranded conductor design enhances the wire’s flex life, making it suitable for applications involving repeated bending and flexing.

- Dimensional Tolerances: Precise dimensional tolerances are essential for ensuring proper fit and integration within the heated hose assembly.

“Effective teamwork begins and ends with communication.” – Mike Krzyzewski