If you’ve ever been in a plant, under the hood of a car, or near an industrial furnace, you know one thing for sure: heat changes everything. It warps metal, destroys insulation, and makes standard electrical wiring useless. Over the years, we’ve seen what happens when people cut corners on wiring in high heat environments.

That’s why we want to discuss high-temperature wire. This isn’t some niche product; it’s a lifesaver for anyone working in conditions where heat is constant. We’ve used it in multiple applications, from automotive systems to industrial equipment, and we’ve learned a few things that might save you time, money, and headaches.

So, What Exactly Is High Temperature Wire?

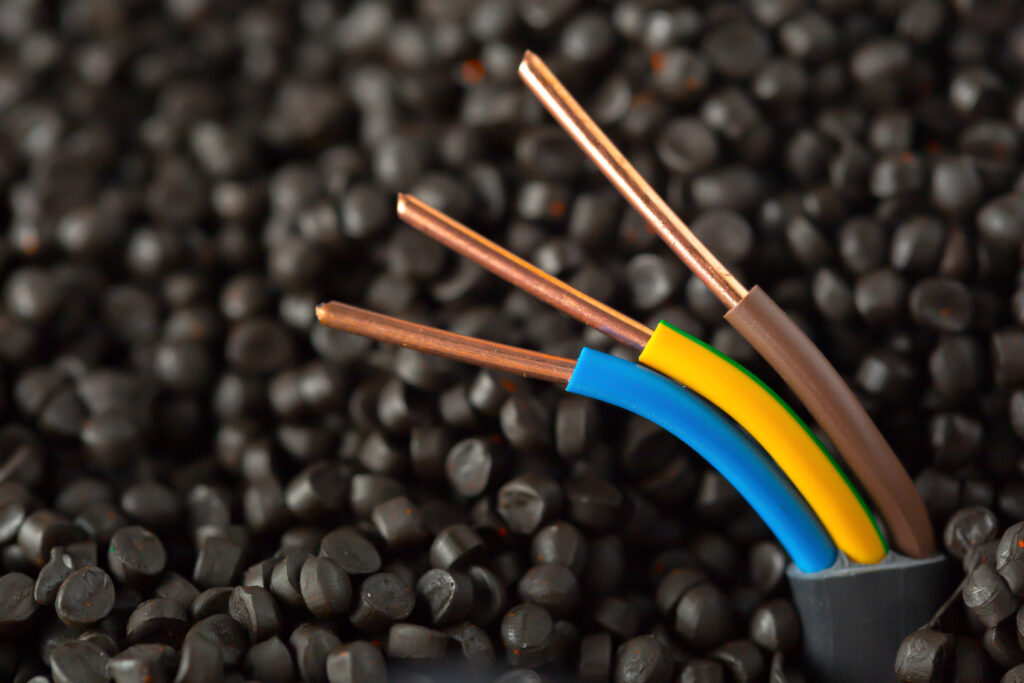

In simple terms, it’s a wire designed to survive in places where standard wire would fail. Ordinary insulation materials like PVC or rubber just can’t handle extreme heat; they melt, crack, and eventually short out.

In simple terms, it’s a wire designed to survive in places where standard wire would fail. Ordinary insulation materials like PVC or rubber just can’t handle extreme heat; they melt, crack, and eventually short out.

Why Bother? Isn’t Standard Wire Good Enough?

We get it if you’re asking this; everybody has been there. Years ago, a client wanted to use regular wire for a heating system. They figured, “Heat-resistant means it can take some heat, right?” Wrong. Within two weeks, the insulation turned brittle, cracked open, and shorted the system. They had to shut everything down to replace the wiring. The downtime cost them thousands just to save a few bucks upfront.

Here’s the thing: high-temperature wire isn’t just about heat. It’s also about safety, durability, and reliability. When you choose the correct wire, you’re protecting your system from:

- Insulation breakdown that could lead to fire.

- Signal or power failure in critical operations.

- Corrosion and chemical damage in harsh environments.

Where Will You See High-Temperature Wire Most Often?

Let us give you a few real-world scenarios where we’ve worked with it:

1. Inside Automotive Engines

Engines get hot, especially around the exhaust and turbo systems. Heat is an even bigger concern in electric vehicles because of high-voltage systems. We’ve used silicone-insulated wires in these setups because they’re flexible and can handle around 200°C without a problem.

2. Industrial Furnaces and Ovens

If you’ve ever walked through a steel plant or a glass factory, you know what “hot” really means. We often use fibreglass-insulated wires or even mica for ultra-high temperatures in these cases. Regular wire wouldn’t last an hour.

3. Aerospace Applications

This one’s fascinating. Aircraft engines and avionics need wires to handle high altitudes, vibration, and massive heat. We’ve worked on projects using PTFE and ceramic insulation because they remain stable even in extreme conditions.

4. Power Generation

Think turbines, nuclear plants, or large generators. These places expose wiring to heat and sometimes corrosive chemicals. Here, ceramic-insulated wires are often the only option.

Different Types of High Temperature Wire (and Why They Matter)

If you think all high-temp wires are created equal, think again. Here are some common types we’ve worked with, along with my thoughts on each:

PTFE (Polytetrafluoroethylene) Wire

- Temp Rating: Around 200°C

- Why You’ll Like It: It’s chemically resistant and has excellent electrical properties, making it perfect for aerospace and medical applications.

- Watch Out For: It can be pricey and a little stiff for tight spaces.

Silicone-Insulated Wire

- Temp Rating: -60°C to +200°C

- Why You’ll Like It: Flexible and easy to work with. Great for cars and robotics.

- Watch Out For: Not the best choice if you need ultra-high heat resistance.

Fiberglass-Insulated Wire

- Temp Rating: Up to 482°C

- Why You’ll Like It: Handles severe heat without breaking a sweat.

- Watch Out For: Can fray if you’re not careful during installation.

Mica-Insulated Wire

- Temp Rating: Up to 1,000°C

- Why You’ll Like It: This stuff is a beast. We recommend it for foundries or kilns.

- Watch Out For: Not very flexible, so plan your routing carefully.

Ceramic-Insulated Wire

- Temp Rating: 1,000°C and above

- Why You’ll Like It: When nothing else works, this does. It is perfect for extreme aerospace or nuclear environments.

- Watch Out For: It’s brittle. Handle it gently during installation.

How Do You Choose the Right One?

We always tell people: don’t pick wire based on price, it’s based on the environment. Here are a few things you need to look at before making a decision:

- Temperature Requirements – What is this wire’s maximum temperature? Add a safety margin to be sure.

- Voltage Rating – Higher voltage? That adds stress to the insulation, especially under heat.

- Flexibility Needs – Does it need to bend often? Go with silicone.

- Environmental Exposure – Chemicals, moisture, or vibration? Make sure your insulation material can handle it.

- Certifications – UL, CSA, MIL-Spec, don’t skip these. They’re there for a reason.

The Upside of Getting It Right

Yes, high-temperature wire costs more upfront. But what you get in return is peace of mind. Here’s what we’ve seen in the field:

- Less Downtime: Systems keep running even under brutal conditions.

- Safety: Reduced risk of fire or catastrophic failure.

- Lower Long-Term Costs: No emergency replacements every few months.

Common Challenges You Might Run Into

Cost Complaints

High-temperature wire does cost more upfront. But compare that to the expense of downtime, repairs, or safety incidents caused by failure. When you frame it that way, the price makes sense.

Installation Issues

Rigid options like ceramic or mica can be tough to route. Avoid sharp bends, plan the layout carefully, and consider silicone-insulated wire if flexibility is a must.

Finding Quality Suppliers

Not all “high temperature” wire meets accurate industry specs. Always stick with trusted

brands and check certifications like UL, CSA, or MIL-Spec before buying.

A Few Maintenance Tips from Experience

Inspect Regularly

Check for cracks, discolouration, or stiff spots in the insulation, signs of heat damage, or ageing.

Store Correctly

Keep the wire in a cool, dry place away from sunlight and moisture to maintain insulation integrity.

Handle with Care

During installation, avoid tight bends and pulling too hard, especially on rigid wires like ceramic or mica.

Before You Choose, Remember This

High-temperature wire isn’t just another line item on your spec sheet; it’s the difference between smooth operations and catastrophic failure. If you’re working in an environment that gets seriously hot, don’t gamble on standard wiring. Choose something built for the job.

If you’re unsure where to start, talk to an expert (and yes, Pelican Wire is a great place to begin). The correct wire might cost more today, but it’ll save you big in the long run.