In modern industry, heating wires are the hidden heroes behind countless manufacturing processes, from plastic molding and packaging to aerospace and semiconductor production. Selecting the right resistance heating wire can dramatically impact the efficiency, longevity, and safety of your equipment. At Pelican Wire, we’ve spent decades perfecting wire designs that meet the unique challenges of industrial heating.

This guide examines the key design considerations to help you make informed decisions when selecting heating wires for industrial applications.

Understanding the Role of Resistance in Heating

At the core of any heating wire is resistance, the property that enables electrical energy to be converted

into heat. The amount of heat generated (P = I²R) depends on both the current and the wire’s resistance. Choosing the correct resistivity is essential: too high, and your system may overheat; too low, and it might not reach the desired temperature efficiently.

Materials like nichrome are commonly used due to their stable resistance, durability, and ability to

withstand high operating temperatures.

Material Selection: The Heart of Performance

Material selection determines how well a heating wire performs over time. Common materials include:

- Nichrome (Nickel-Chromium Alloys): The most widely used heating wire material, valued for its oxidation resistance and ability to perform at temperatures exceeding 1100°C (2010°F).

- Kanthal (FeCrAl Alloys): Ideal for high-temperature environments where oxidation resistance and longer lifespan are critical.

- Copper-Nickel (CuNi) Alloys: Suitable for lower-temperature applications or where precise temperature control is needed.

At Pelican Wire, material composition is carefully matched to your operating temperature range,

environmental conditions, and electrical requirements.

Temperature Range and Stability

Different processes require vastly different temperature ranges. For example:

- Food processing lines might need stable, moderate temperatures (200–400°F).

- Glass manufacturing or metal hardening could demand temperatures exceeding 1000°C.

Each material’s maximum continuous operating temperature (MCOT) and melting point must align with

the application. Stability over repeated thermal cycles is also critical; wires must maintain resistance

consistency even after thousands of heat-up and cool-down cycles.

Environmental Considerations

The surrounding environment can be just as important as electrical performance. Consider:

- Oxidizing atmospheres: Nichrome excels in this environment, forming a protective chromium oxide layer.

- Corrosive or humid conditions: Specialty coatings or insulation may be needed.

- Vacuum or inert gas systems: Require materials that won’t outgas or degrade in low-oxygen settings.

Pelican Wire offers custom coatings and insulation options, including fiberglass, PTFE, and ceramic

coatings, to protect the wire and extend its lifespan in harsh environments.

Wire Gauge and Configuration

The gauge (diameter) directly impacts resistance and heat distribution. Thicker wires carry more current but produce less resistance per foot, while thinner wires offer higher resistance and faster heating but can be fragile.

Wire configurations also vary:

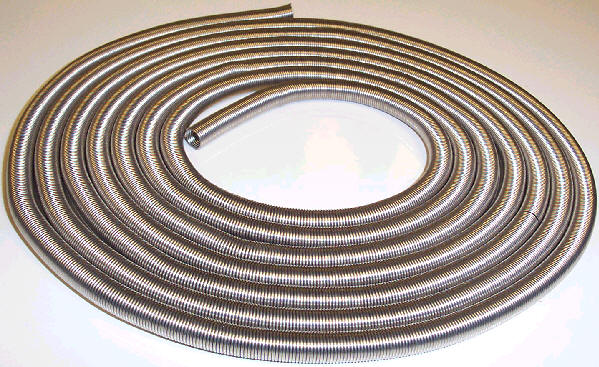

- Straight or coiled wire: Common for toasters, ovens, and kilns.

- Ribbon wire: Provides greater surface area and uniform heat distribution.

- Twisted or stranded wire: Offers flexibility and strength for dynamic or moving applications.

Pelican Wire engineers work closely with clients to design the ideal geometry for each use case, striking a balance between electrical performance and mechanical strength.

Insulation and Sheathing Materials

Insulation isn’t just about electrical safety; it also affects heat transfer and mechanical durability.

Common insulation types include:

- Fiberglass or silica: For high-temperature resilience.

- PTFE (Teflon): For chemical resistance and flexibility.

- Ceramic beads or coatings: For ultra-high temperatures and stability.

Proper insulation selection ensures the wire maintains its performance, even in continuous-duty

environments.

Safety and Regulatory Compliance

Safety cannot be overlooked. Heating wires used in industrial equipment must meet UL, CSA, or ISO

certifications, depending on regional requirements.

Pelican Wire ensures full traceability and testing of every batch, providing confidence in performance and compliance.

Customization for Specialized Applications

No two industrial systems are alike. That’s why custom engineering is often the best approach.

Custom parameters may include:

- Resistance per foot

- Operating voltage and current

- Surface load and temperature uniformity

- Coil pitch and geometry

- Terminal connections and lead configurations

Energy Efficiency and Lifecycle Costs

Choosing the right wire isn’t only about upfront cost. The total cost of ownership includes efficiency,

energy consumption, and maintenance intervals.

A properly designed resistance wire system can save thousands of dollars annually by reducing energy

waste and preventing premature failures.

Precision in Every Wire

Selecting the right heating wire for industrial use is both an art and a science. It demands careful attention to electrical, mechanical, and environmental factors, all of which Pelican Wire has mastered through decades of innovation and engineering excellence.

Whether you need nichrome, Kanthal, or custom alloy solutions, Pelican Wire provides engineered

resistance wire products that perform reliably under pressure, helping your operations run safer, longer,

and more efficiently.