Built for reliability. Engineered for care.

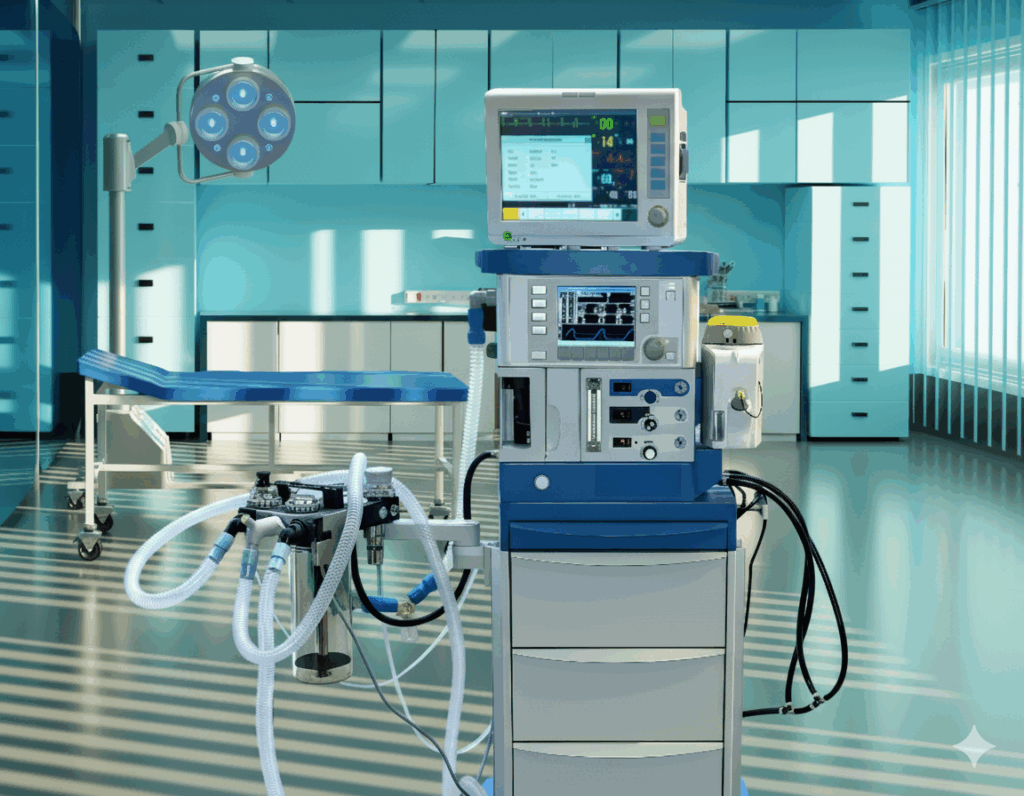

As demand for high-performance medical technology grows, so does the need for wire solutions which deliver consistent electrical behavior, withstand elevated temperatures, and integrate cleanly in compact assemblies. Pelican Wire designs and manufactures custom resistance wire used by medical OEMs in respiratory and other life-sustaining equipment, where stability and reliability matter most.

What sets our medical-grade resistance wire apart

- Stable electrical performance

Nickel-bearing resistance alloys are selected for predictable resistivity, corrosion resistance, and low temperature coefficient, which supports accurate control in sensing and heating circuits without disclosing proprietary recipes. - High-integrity insulation

Medical-grade fluoropolymer insulation provides excellent dielectric strength, chemical resistance, and heat tolerance while remaining flexible for tight routing inside compact electromechanical assemblies. - Manufactured for consistency

Tight in-process controls, calibration routines, and layered quality checks help ensure repeatable electrical and mechanical performance, without revealing specific machine models, settings, routings, or acceptance thresholds.

Typical use cases in respiratory care

- Temperature sensing & control (e.g., feedback loops in air pathways)

- Resistive heating for condensation management in humidification circuits

- Low-noise signal paths in patient-monitoring subsystems

(Final product design, regulatory compliance, and suitability are determined by the device manufacturer/OEM.)

Scalable supply with full traceability

Over the past decade, Pelican Wire has supported significant surges in medical equipment demand with scalable production, short communication loops, and end-to-end lot traceability. Customers depend on our responsiveness to urgent supply chain needs and our ability to replicate performance across large volumes, without exposing facility layouts, capacity data, or cycle times.

What we purposefully don’t publish

To protect our customers and our IP, we avoid sharing: exact gauges tied to use cases, resistance-per-length values, insulation thicknesses, unique tolerances, processing parameters, tooling/fixtures, routings, control plans, supplier mixes, or line layouts. If you need a data sheet, our engineering team can provide application-appropriate specifications under NDA.

Collaboration without guesswork

Bring us your application, target electrical behavior, environment, and regulatory constraints. Our engineers will help translate those into a balanced construction (alloy, gauge range, insulation family, and test plan) that meets your performance goals while respecting sterilization, biocompatibility, and assembly considerations.

Let’s engineer it together.