In the world of industrial heating, the demand for high-performance, flexible, and durable heating elements is constantly growing. For applications where standard resistance wires fall short, glass core heater wire emerges as a superior solution, offering a unique combination of flexibility, strength, and high-wattage output. This article explores the design principles of glass core heater wire, its key advantages, and the diverse range of applications where it excels.

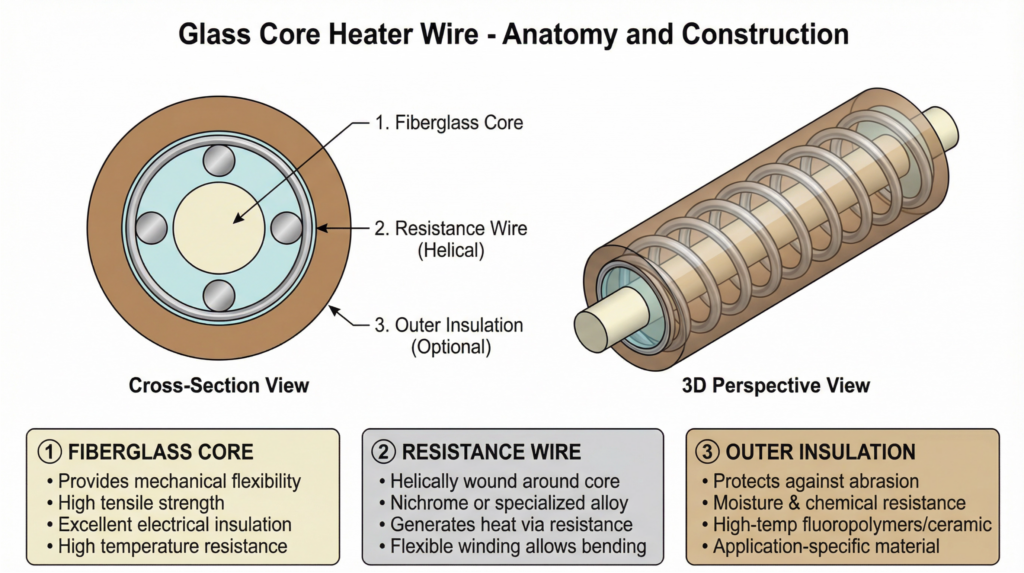

The Anatomy of a Glass Core Heater Wire

A glass core heater wire is a composite construction, meticulously engineered to deliver precise heating in demanding environments. Its design typically consists of three main components:

- The Fiberglass Core: At the heart of the wire is a fiberglass cord. This core provides the mechanical backbone of the wire, giving it exceptional flexibility and tensile strength. The fiberglass is an excellent electrical insulator and can withstand high temperatures, making it an ideal substrate for the resistance element.

- The Resistance Wire: Helically wound around the fiberglass core is the resistance wire itself. This can be a single strand or multiple strands of a specific resistance alloy, such as Nichrome, or other specialized alloys depending on the required operating temperature and resistance. The helical winding allows the wire to flex and bend without putting excessive strain on the conductor, which is crucial for dynamic applications.

- Optional Outer Insulation: Depending on the application, the glass core heater wire can be used as-is, or it can be encapsulated in an outer layer of insulation. This insulation provides additional protection against abrasion, moisture, and chemical exposure, and can be made from a variety of materials, including high-temperature fluoropolymers or ceramic fibers, to meet specific environmental challenges

Key Advantages of Glass Core Heater Wire

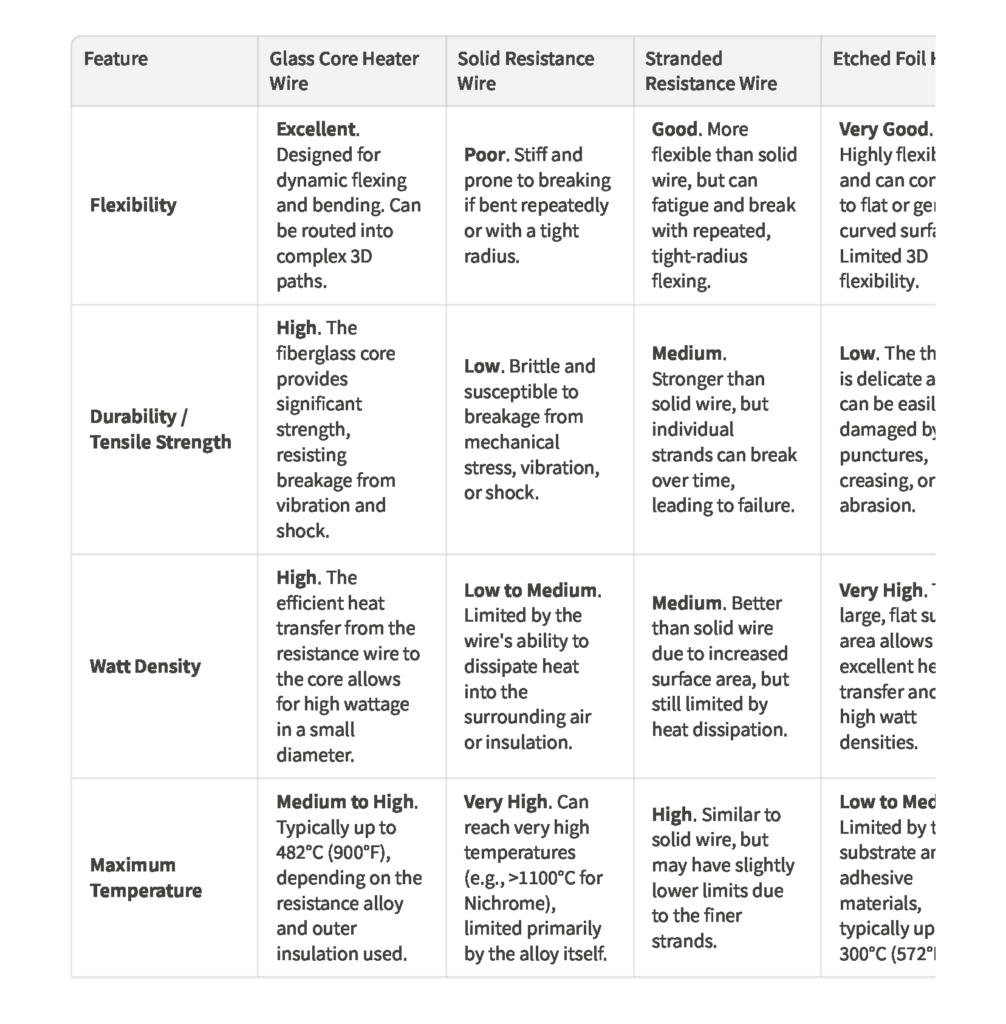

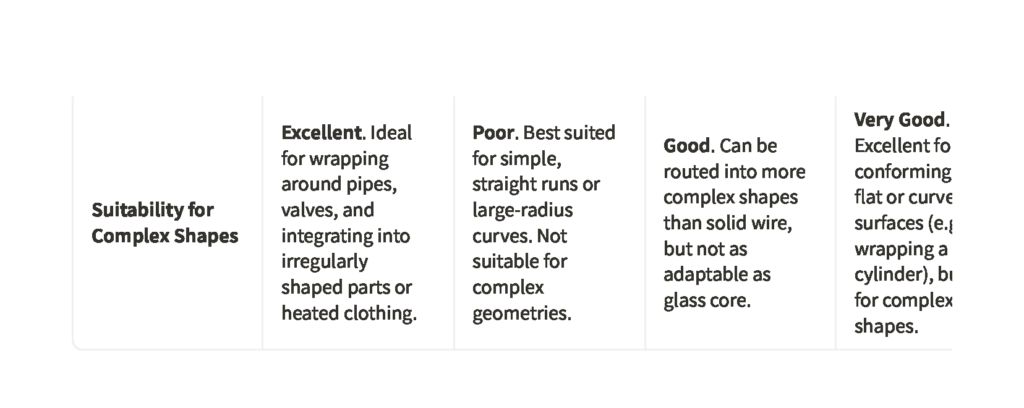

The unique construction of glass core heater wire provides several distinct advantages over traditional solid or stranded resistance wires:

- Exceptional Flexibility: The fiberglass core allows the wire to be bent, twisted, and routed into complex geometries without compromising its structural integrity or electrical performance. This makes it ideal for applications with tight spaces or where the heating element needs to conform to an irregular shape.

- High Mechanical Strength: The fiberglass core provides significant tensile strength, making the wire resistant to breakage from vibration, shock, and repeated flexing. This durability is critical in applications such as heated hoses and aerospace systems, where reliability is paramount.

- High Wattage Density: The design of glass core heater wire allows for a higher wattage output per foot compared to many other types of heating elements. This is because the resistance wire is in close contact with the fiberglass core, which acts as a heat sink and helps to dissipate heat more effectively.

- Customizable Design: Glass core heater wires are highly customizable. The resistance, wattage output, and flexibility can be tailored to specific application requirements by varying the type and gauge of the resistance alloy, the number of strands, the winding pitch, and the core diameter.

Applications of Glass Core Heater Wire

The versatility of glass core heater wire makes it suitable for a wide range of applications across various industries. Some of the most common applications include:

- Heated Hoses: In industries such as food and beverage, chemical processing, and automotive, heated hoses are used to maintain the temperature of fluids as they are transferred from one point to another. Glass core heater wire is the ideal heating element for these hoses due to its flexibility, durability, and ability to provide uniform heating over long lengths.

- Aerospace and Defense: In aircraft and other aerospace applications, glass core heater wires are used in fluid systems to prevent freezing at high altitudes. The lightweight and high-reliability nature of these wires make them a perfect fit for mission-critical applications where failure is not an option.

- Composite Curing: The manufacturing of composite materials, such as those used in the aerospace and automotive industries, often requires precise and uniform heating to cure the resin. Glass core heater wire can be integrated directly into the mold or wrapped around the part to provide the necessary heat for the curing process.

- Freeze Protection: In cold climates, glass core heater wire is used to prevent pipes, valves, and other equipment from freezing. The flexibility of the wire allows it to be easily wrapped around complex shapes, providing targeted heating where it is needed most.

- Heated Seats and Personal Comfort: The flexibility and durability of glass core heater wire also make it suitable for use in heated seats for automobiles, as well as in other personal comfort applications such as heated clothing and blankets.

Designing with Glass Core Heater Wire

When designing a heating system with glass core heater wire, it is important to consider the following factors:

- Operating Temperature: The maximum operating temperature of the heating element will determine the type of resistance alloy and insulation that should be used.

- Wattage Requirements: The required wattage output will influence the resistance of the wire, which can be adjusted by changing the alloy, gauge, and length of the conductor.

- Flexibility and Mechanical Stress: The degree of flexibility and the amount of mechanical stress the wire will be subjected to will determine the required core diameter and winding pitch.

- Environmental Conditions: The presence of moisture, chemicals, or abrasive materials will dictate the need for an outer insulation layer and the type of material that should be used.

By carefully considering these factors, engineers can design a glass core heater wire solution that is optimized for their specific application, ensuring reliable and efficient heating performance for years to come.

Conclusion

Glass core heater wire represents a significant advancement in heating element technology, offering a unique combination of flexibility, strength, and high-wattage output. Its customizable design and ability to perform in demanding environments make it the ideal solution for a wide range of applications, from heated hoses and aerospace systems to composite curing and freeze protection. As industries continue to push the boundaries of technology, the demand for high-performance heating solutions like glass core heater wire will only continue to grow.