If you’re working with resistance heating wire for projects like foam cutters, plastic welders, or heating

elements, understanding Ohm’s Law isn’t just helpful—it’s essential. This fundamental electrical principle governs how your nichrome wire performs and helps you design safe, efficient heating applications.

What Is Ohm’s Law and Why Does It Matter?

Ohm’s Law describes the relationship between voltage, current, and resistance in an electrical circuit.

Named after German physicist Georg Ohm, this principle states that the current flowing through a

conductor is directly proportional to the voltage and inversely proportional to the resistance.

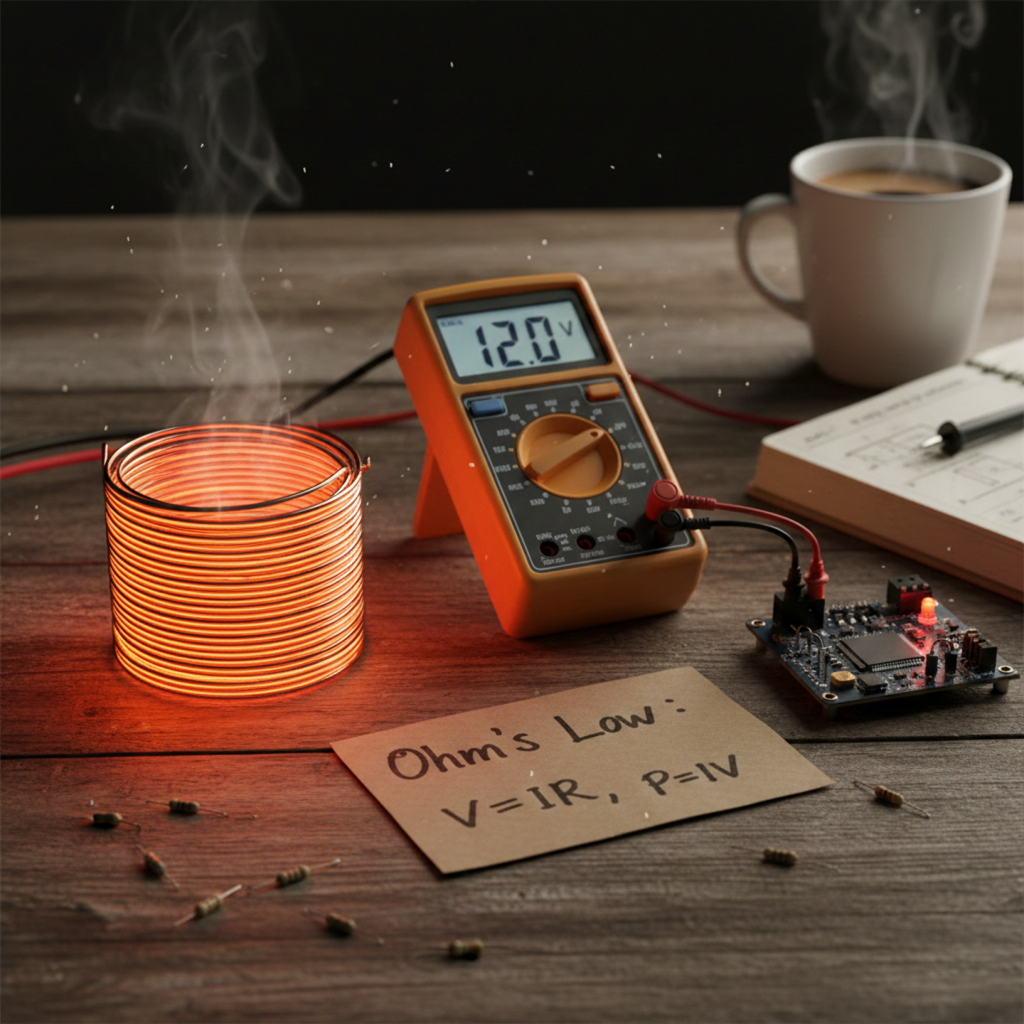

The mathematical expression is beautifully simple: V = I × R, where V represents voltage in volts, I

represents current in amperes (amps), and R represents resistance in ohms. This equation can be

rearranged to solve for any variable: I = V/R or R = V/I.

For resistance heating applications, Ohm’s Law serves as the foundation for calculating the temperature

of your wire, the required power, and whether your power supply can safely handle the load. Get these

calculations right, and you’ll have a perfectly functioning heating element. Get them wrong, and you risk

burning out a wire, overloading your power supply, or creating a safety hazard.

The Power Equation: Where Heat Comes From

While Ohm’s Law tells us about voltage, current, and resistance, we need another equation to understand heat generation: the power equation. Power (P), measured in watts, represents the rate of energy conversion and can be calculated using P = V × I. By combining this with Ohm’s Law, we get additional useful formulas: P = I² × R and P = V² / R.

These power calculations are crucial because the power dissipated by your resistance wire directly

correlates to the heat it produces. Every watt of electrical power flowing through your nichrome wire

converts to heat energy. This is why understanding these relationships helps you design heating elements that operate at exactly the right temperature for your application.

Understanding Wire Gauge and Resistance

The gauge of nichrome wire significantly impacts its resistance and heating characteristics. Thinner wire

(higher gauge numbers) has more resistance per foot than thicker wire. For example, 26-gauge nichrome wire has approximately 4.0 ohms per foot, while 22-gauge has about 1.3 ohms per foot.

This relationship creates interesting trade-offs in heating applications. Thinner wire heats up faster with

less power because of its higher resistance, but it’s also more fragile and can burn out more easily.

Thicker wire requires more power to reach the same temperature but offers greater durability and

longevity.

When selecting wire gauge for your project, consider both the power available from your supply and the

physical demands of your application. A handheld foam cutting tool might benefit from thinner wire that

heats quickly, while a large industrial cutter would use thicker wire that can withstand continuous

operation.

Voltage Selection and Its Impact

The voltage you choose for your resistance heating application dramatically affects performance. Higher voltage pushes more current through the same resistance, generating more power and heat. However, this relationship isn’t linear because power increases with the square of voltage (P = V² / R).

Doubling the voltage doesn’t just double the power—it quadruples it. If our foam cutter example used 24 volts instead of 12 volts, the power would increase from 27.7 watts to 111 watts. This might sound

appealing for faster cutting, but it could easily burn out the wire or make it too hot for controlled cutting.

Most DIY heating applications work well with voltages between 12 and 24 volts. These voltages are

relatively safe to work with and readily available from standard power supplies. Lower voltages require

thicker wires or shorter lengths to generate adequate heat, while higher voltages risk damaging the wire or creating safety hazards.

Current Capacity and Power Supply Selection

Your power supply must deliver sufficient current to heat your nichrome wire properly. Using our foam

cutter example, which requires 2.31 amps, you’d want a power supply rated for at least 3 amps to provide a comfortable safety margin. Running a power supply at its maximum capacity continuously can cause overheating and premature failure.

Many beginners make the mistake of focusing only on voltage when selecting a power supply. A 12-volt

supply rated for 1 amp cannot adequately power our foam cutter example, even though the voltage

matches. The supply would either fail to deliver sufficient current, operate in an unsafe overload condition, or shut down due to over-current protection.

Variable power supplies offer excellent flexibility for resistance heating projects. By adjusting the voltage, you can control the temperature of your heating element without changing the wire. This adaptability is particularly valuable when working with different materials or when fine-tuning your setup for optimal performance.

Series and Parallel Wire Configurations

Understanding how resistance behaves in series and parallel circuits opens up more design possibilities.

When connecting multiple lengths of nichrome wire in series (end to end), the total resistance equals the sum of individual resistances. This increases overall resistance and reduces current flow for a given

voltage.

Parallel connections, where wires share the same start and end points, decrease total resistance. The

formula for two equal resistances in parallel is R_total = R / 2. This configuration draws more current and

generates more total power, useful for applications requiring higher heat output or larger heating areas.

Safety Through Proper Calculations

Proper application of Ohm’s Law isn’t just about getting your project to work—it’s about keeping it safe.

Undersized wiring in your power circuit can overheat and create fire hazards. Overloading your power

supply can cause failures or dangerous conditions. Operating nichrome wire at excessive power levels

can cause it to burn out suddenly, potentially showering sparks or igniting nearby materials.

Always calculate your expected current draw and verify that every component in your circuit—including

power supplies, switches, connectors, and wiring—is rated to handle that current with appropriate safety margins. Use fuses or circuit breakers sized appropriately for your application to protect against short circuits or unexpected overloads.

Temperature Considerations

An important factor that many newcomers overlook is that nichrome wire’s resistance increases slightly as it heats up. This property means your wire will draw less current as it reaches operating temperature than it does when cold. For most practical applications, this change is relatively small, typically ranging from 2 to 3 percent over the operating temperature range. However, the initial surge of current when the cold wire first powers up can be notably higher than the steady-state current during operation.

Practical Tips for Success

When building resistance heating projects, measure actual resistance with a multimeter rather than relying solely on specifications. Manufacturing variations and connection resistances can affect your calculations. Start with lower voltages and increase gradually while monitoring wire temperature. Keep detailed notes of voltages, currents, and performance for different configurations.

At Pelican Wire, we understand that successful heating projects are built on the combination of high-

quality materials and sound electrical principles. Take time to do the calculations, select appropriate

components, and test carefully. Your understanding of these principles will serve you well across

countless projects and applications.