Heating wire is everywhere: inside ovens, industrial heaters, sealing machines, lab equipment, and many other systems that depend on steady, reliable heat. But when someone starts shopping for heating wire, one question comes up fast:

What temperature can this wire handle?

That’s a smart question because temperature range is one of the most important things to consider when choosing the right heating wire for your application. If you choose a wire that runs too hot for its rating, it may burn out quickly, lose efficiency, or become unsafe. But if you pick a wire that’s designed for much higher heat than you need, you may be spending more than necessary.

At Pelican Wire, we work with customers across industries to help them choose heating wires that perform safely, last longer, and meet real-world requirements. In this blog, we’ll break down heating wire temperature ranges in a clear, practical way, without getting overly technical.

Why Temperature Range Matters for Heating Wire

Temperature isn’t just a number on a spec sheet. It directly affects:

- How long the wire will last

- How safely it performs

- How consistent the heat output is

- How often maintenance or replacement is needed

- How efficient your heating system runs

When a heating wire operates inside its designed temperature range, it works smoothly for a long time. But when it’s pushed beyond that range, you can see problems like

- Wire breakage

- Hot spots and uneven heating

- Faster oxidation (surface wear)

- Reduced heat output over time

- Higher risk of failure in the equipment

That’s why temperature range should never be an afterthought; it should be one of the first things you evaluate.

What “Temperature Range” Really Means

When manufacturers talk about the temperature range for heating wire, they’re usually referring to the maximum temperature the wire can handle during regular use.

That doesn’t mean the wire instantly fails above that temperature, but it does mean performance becomes less reliable. Think of it like tires on a car: driving slightly above the speed rating might work briefly, but it’s not a good idea long-term.

Also, heating wire temperature isn’t always the same as the temperature of the air or surface around it. The wire itself can be hotter than the environment, especially if it’s tightly coiled or packed into a small space.

So, it’s important to design heating systems with a margin of safety, not right at the limit.

Common Heating Wire Types and Their Temperature Ranges

Different heating wires have different strengths. Some are best for medium-heat applications, while others are built for extreme heat. Here are a few common categories, explained in simple terms:

1. Standard Resistance Heating Wire

Resistance heating wire is made specifically to generate heat when electricity flows through it. These wires are used in appliances and industrial heating elements.

Many resistance heating wires work well across moderate to high temperatures, but the exact range depends on the alloy and how the wire is installed.

2. Nichrome Heating Wire

Nichrome is one of the most widely used heating wires because it provides dependable performance and can handle high heat. It’s used in everything from electric furnaces to packaging machines.

Nichrome is popular because:

- It heats evenly

- It holds up well in repeated heating cycles

- It lasts longer than many lower-grade wires

3. High-Temperature Specialty Wires

Some environments require even tougher materials, especially when you need constant high temperatures, outdoor exposure, or harsh factory conditions. These wires often include special alloys, insulation, or coatings.

At Pelican Wire, we can help you match the right high-temperature option to your exact system setup.

What Affects How Hot a Heating Wire Can Get?

Even if two wires are made of the same material, they may not perform the same. Temperature range is influenced by how the wire is used, not just what it’s made of.

Here are the significant factors:

1. Wire Thickness (Gauge)

Thicker wire often holds up better physically, while thinner wire can heat faster. But thinner wire may also wear out quicker if pushed too hard.

Choosing the right gauge helps you balance:

- Strength

- Heat speed

- Durability

- Overall lifespan

2. Airflow and Ventilation

Heating wire in open air usually stays more stable than wire trapped in a tight space. If the wire can’t “breathe,” heat builds up faster and can shorten its life.

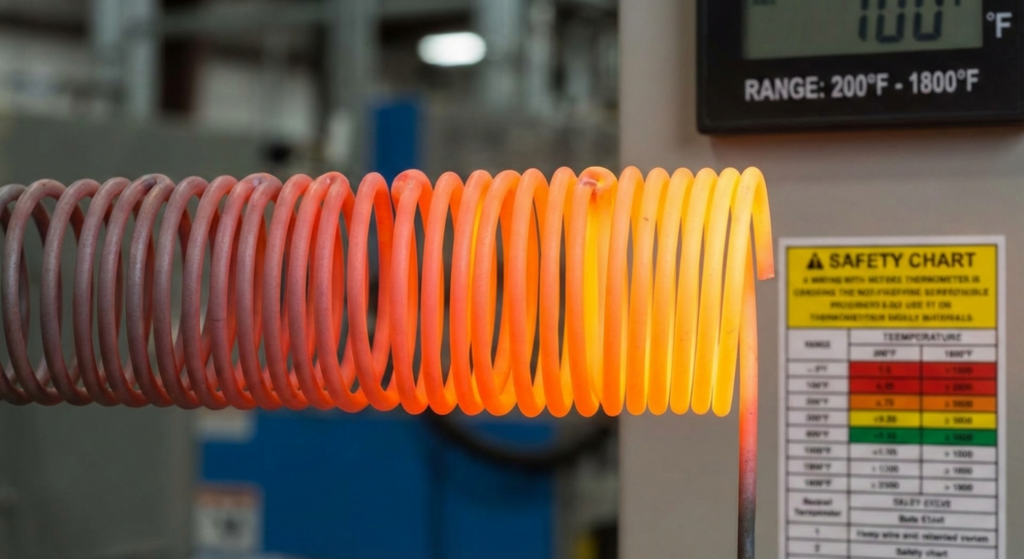

3. Coil Shape and Spacing

Coiled wire is common because it’s compact and produces good heat. But spacing matters.

If coils are too close together:

- They may create hot spots

- Heat may build unevenly

- Wire life may decrease

4. Insulation and Surrounding Materials

Some heating wires are installed with insulation or inside ceramic parts. That can be great for safety and protection, but it also affects heat movement.

The wrong insulation for high heat can break down, crack, or become brittle. The right insulation can protect the wire and help it last longer.

5. Power Input and Control System

If your system is feeding too much power too fast, the wire can overshoot its ideal temperature. A good temperature control setup prevents overheating and improves consistency.

What Happens When a Heating Wire Runs Too Hot?

Overheating doesn’t always look dramatic at first. Often, performance slowly declines until failure happens.

Some common warning signs include:

- The wire stops heating evenly

- A section of wire darkens or thins

- Heating time becomes longer

- The wire becomes fragile or breaks during maintenance

- You see more frequent element replacement

These problems lead to unplanned downtime, higher repair costs, and reduced production efficiency.

If your heating wire keeps failing early, temperature mismatch may be the reason.

Choosing the Right Temperature Range (Without Overbuying)

Here’s a practical way to think about it:

- If your system needs moderate heat, choose a wire that performs reliably slightly above that level.

- If your system needs high heat, choose a wire designed for continuous high-temperature use.

- Always give yourself a “buffer” so you’re not running right at the maximum limit.

It’s like buying a ladder; you don’t want one that barely reaches the top. You want one that reaches safely and comfortably.

How Pelican Wire Helps You Choose the Right Heating Wire

At Pelican Wire, we understand that customers don’t just want wire; they want reliability. Our job is to make sure your wire matches your equipment needs.

We support customers by helping with:

- Selecting the right wire material

- Choosing wire gauge and length

- Planning for safe operating temperature

- Improving heating performance and lifespan

- providing consistent quality from batch to batch.

Whether you need standard heating wire or high-performance industrial-grade options, Pelican Wire is ready to help.