An autoclave is a device used to perform industrial and medical or scientific processes requiring elevated temperature and pressure. A simple example of an autoclave is a stove top pressure cooker like those used for cooking or canning. In these simple pressure cookers, the combination of high pressure and steam cause foods to cook faster. In large industrial food production applications these cookers are free standing and are commonly referred to as retort cookers. For medical applications autoclaves can serve to sterilize glassware, surgical instruments, and medical waste. The sterilization of glassware is important to the pharmaceutical industry for example. Like canning jars, drug vials and other containers need to be sterilized prior to filling. Typically this is done by subjecting the objects to be sterilized to pressurized saturated steam at 121C for 30 60 minutes depending on load. Autoclaves are often used to cure composites and vulcanize rubber. When laminating multiple layers of composite material the heat and pressure in the autoclave eliminate voids that could reduce material strength or performance. With composites being used extensively in the aerospace industry autoclaves have been made large enough to hold entire aircraft fuselages.

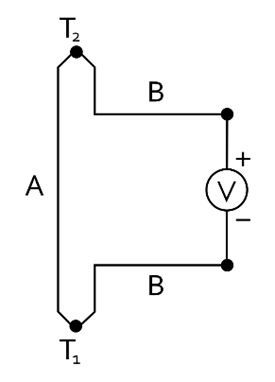

Temperature measurement monitoring is crucial to the proper performance of autoclaves and to the desired outcome occurred. Thermocouples are commonly used for this function. A thermocouple is a transducer that changes temperature differences into a small amount of voltage (The Seebeck Effect). This voltage called electromotive force (EMF) is measured in millivolts.

Diagram of The Seebeck Effect

This EMF data is sent to process instrumentation along the thermocouple wire for monitoring and recording purposes.

Pelican Wire manufactures a unique thermocouple wire that is specifically designed for autoclave applications. This wire called HBond was engineered to resolve a problem encountered in monitoring temperatures in autoclaves. As mentioned earlier the atmosphere in autoclaves is one of high temperatures and pressure sometimes including super-heated water or steam. With conventionally constructed thermocouple wire there are a pair of legs, one positive and one negative, each individually insulated then surrounded by an overall jacket. As these wires are stripped and connected to a thermocouple probe which is then placed in the autoclave there is the possibility of leakage of water or steam due to the pressure in the vessel and potential gaps in the overall jacket. In extreme cases this leakage could travel the length of the wire and could enter the process monitoring instrumentation. Pelican’s HBond manufacturing process eliminates the need for the outer jacket on the thermocouple wire while still insulating the single leg. By eliminating the outer jacket a 95% reduction of leakage has been proven making this wire safer for equipment and ensuring the integrity of the autoclave process. Pelican makes HBond thermocouple wire in Type J, K, and T in solid and stranded conductor with FEP and PFA insulations. Special Limits of Error is standard and Ultra Premium accuracy wire is available in some Types and gauges.

To learn more about Pelican Wire & our capabilities, please visit us online at pelicanwire.com or reach our Sales team at 1+(239) 597-8555 or [email protected]